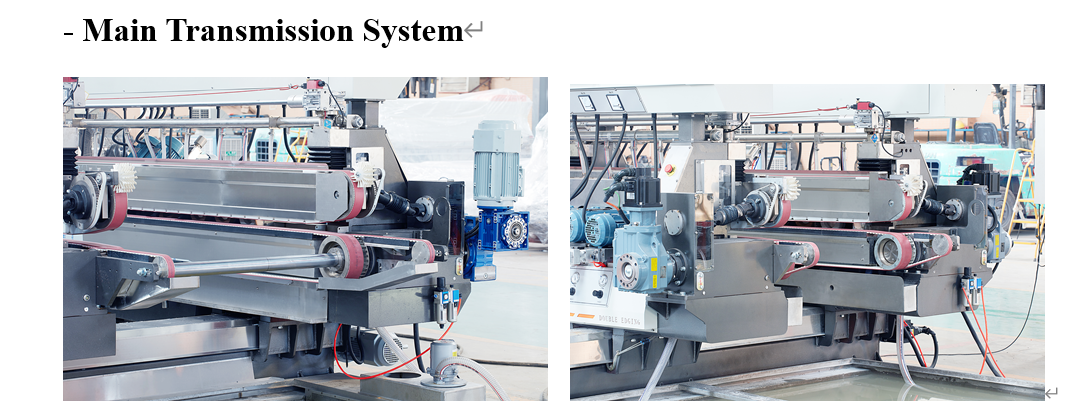

- The main gear box shaft sleeve adopts through sleeve structure, using high precision roller bearings, stable and reliable operation, long service life, reduce maintenance cost. Servo motor transmission is also available for option.

1. Standard Model: High performance ABB motors first one adopts 3kw. Inside of the sliding part adopt the bronze nut work with adjustment screw rod to reduce the gap, more flexible and durable.

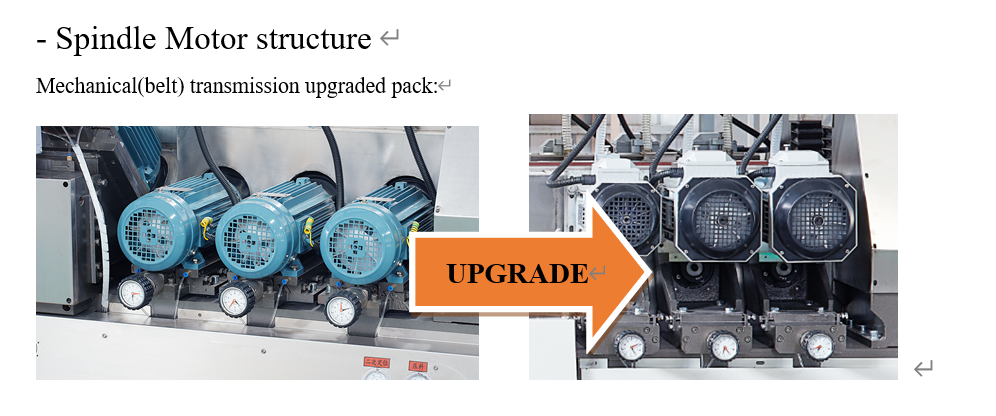

2. Mechanical (belt) transmission: with 4200rpm mechanical transmission by belt driven. Spindles shaft rotation at 4200rpm/min. The shaft can tolerant up to 12000rpm/min maximum, however, only using 1/3 of total speed capacity. The processing speed is upon 15m/min with polishing. Grinding ability has improved.

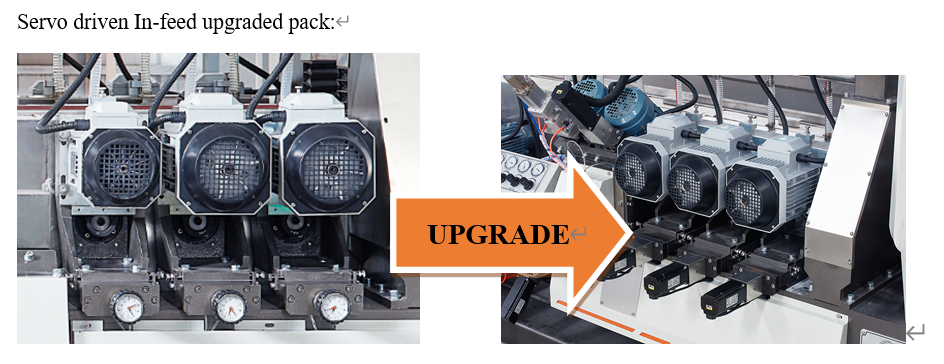

3. Mechanical (belt) transmission with Servo driven In-feed arrangement: Fully automatic wheel adjustment. Precise calculation between wheel and material. Avoiding uneven grinding caused by human error. Stepping into the next automation level.

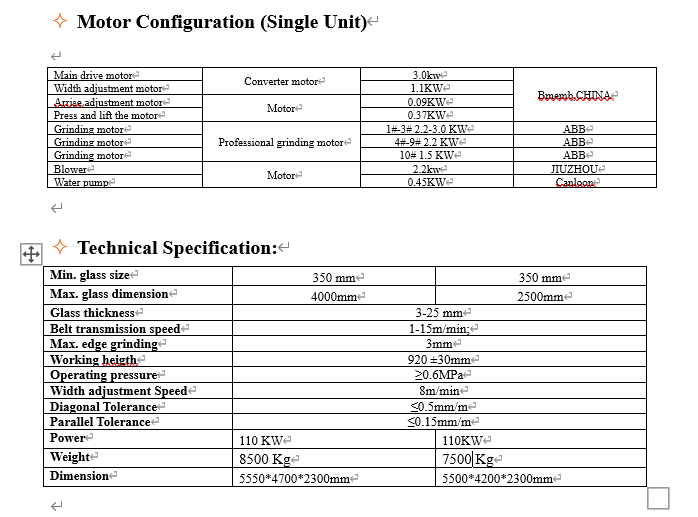

1. Motor configuration:

- Conveyor motor: variable frequency motor 2.2KW

- Roller conveyor motor 1: variable frequency motor 1.5KW

- Roller conveyor motor 2: variable frequency motor 1.5KW

2. Technical parameters:

1 | Minimum size of the transfer glass: | 350mm * 350mm |

2 | Maximum size of the transfer glass | 2500mm * 1500mm |

3 | Thickness of the transfer glass | 3-25mm |

4 | Total power | 5.2KW |

5 | Dimensions | 8100mm * 2900mm * 1000mm |

Remark: When the size of the transfer glass changes, the external dimensions change accordingly. | ||

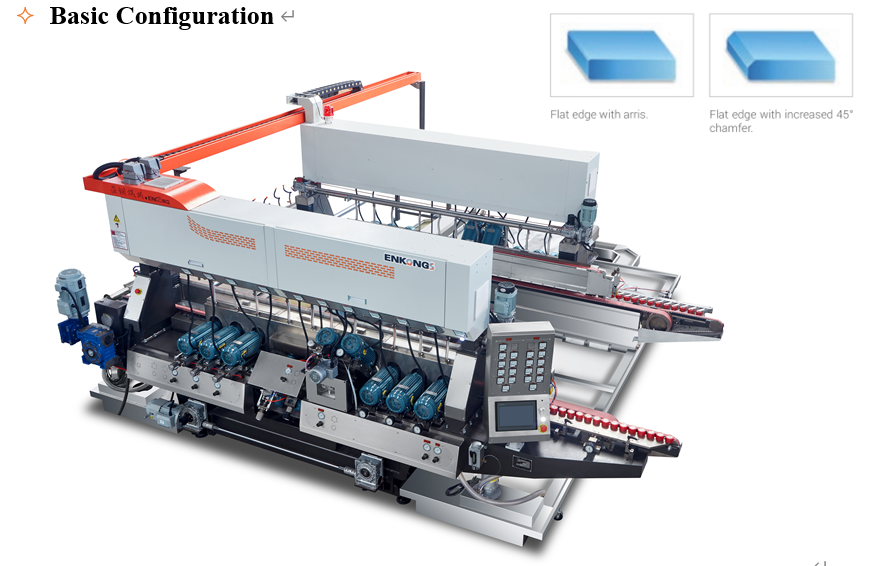

In the realm of glass processing, the art of precision and efficiency is paramount. These sophisticated tools are the linchpins in the glass manufacturing industry, enabling the creation of smooth, precise edges and corners that are both aesthetically pleasing and safe.

Glass grinding machinery is designed to handle an array of tasks, from simple to complex. The glass edge grinding machinery, for instance, is instrumental in shaping the glass edges to the desired finish, whether it be straight, beveled, or rounded. This process not only enhances the appearance of the glass but also ensures that it is safe to handle, reducing the risk of injury from sharp edges.

Glass corner grinding machines are engineered to deal with the tricky task of smoothing out the corners of glass panels. These machines are often equipped with diamondtipped wheels that can grind through the glass with ease, creating perfect 90degree angles or even softer, rounded corners. The precision of these machines is such that they can work on both small batches and largescale production runs with consistent results.

The glass corner polishing machine is a specific type of glass grinding machinery that takes the finishing process a step further. After the corners have been ground to the required shape, the polishing machine steps in to ensure a highquality, sparkling finish. This is particularly important for glass products that are destined for display or highend applications where the visual appeal is just as important as the functional aspect.

Glass grinder machines are the workhorses of the glass processing industry. They are typically robust and versatile, capable of handling a wide range of glass types and thicknesses. These machines are essential for the initial shaping of glass sheets before they are sent for further processing on more specialized equipment.

The efficiency and precision of these glass grinding machines have revolutionized the glass manufacturing process. They offer a combination of speed and accuracy that is simply not achievable by hand, enabling manufacturers to meet tight production schedules and highquality standards. Moreover, the advanced features of these machines, such as automated controls and multiple grinding heads, allow for a variety of operations to be performed on a single machine, thereby streamlining the production process.

Glass grinding machinery, including glass edge grinding machinery, glass corner grinding machines, glass corner polishing machines, and glass grinder machines, play a pivotal role in the glass manufacturing industry. They are the keys to producing glass products that are not only functional but also meet the high aesthetic standards demanded by today's consumers. As technology advances, we can expect these machines to become even more sophisticated, pushing the boundaries of what is possible in glass processing.