General description:

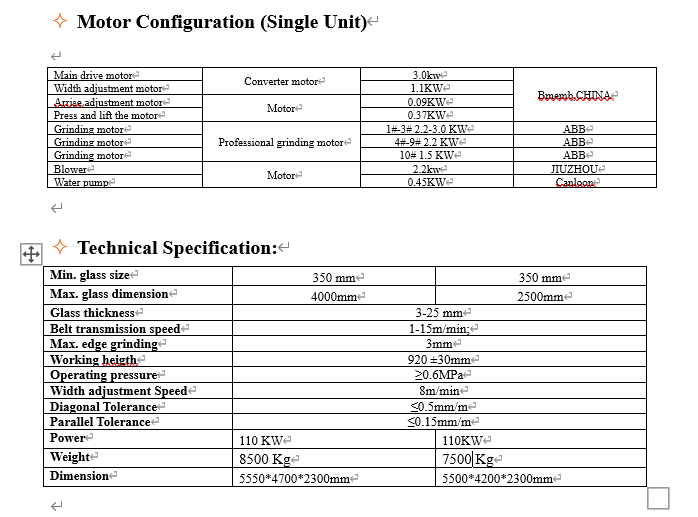

1. SM24 glass double edging machine adopted to auto-polish feeding senor, optimizing polish level.

2. SM24 glass double side polisher Suitable for high polish demanded products, such as household appliances and furniture.

3. SM24 glass double edging machine body and components especial stable design for low vibration processing and ensure tolerance of the diagonal within ±0.5mm in 1m^2.

Basic configuration of SM24 glass double side polisher

1, ball screw: Taiwan HINWIN/TBI/PMI(or the same grade brand)

2, linear guide rail: Taiwan HINWIN/TBI/SHAC(or the same brand)

3, base, girder, conveying plate: the use of high-quality steel plate welding after heat treatment and finishing

4, grinding head water tank material: SUS304 (floor water tank non-standard, need to be selected)

5, synchronous belt: ring seamless high-intensity belt

6, control mode: PLC+ touch screen control automatic PLC computer control, touch screen human-computer interaction interface, simple and intelligent operation

The glass edger machine using PLC +Touchscreen with centralized-control system. The operator canmonitor the current of each motor by control center, Please check the red circle with currentmeter, You can check the situation of motor by both of them, double-monitor system.<

The glass edger machine beam in 20mm steel, thick base to keep glass transfer smoothly, reliable use.CNCmachinig ←

Transmission beam with $CM solid steel, and with stress relief heat treatment. ulti point fixed, tokeep transfer smoothly and will never changee

[The glass processing machine is a precision tool essential for the glass processing industry. glass processing machine is designed to smoothly grind and refine the edges of glass, ensuring safety and enhancing the visual appeal of glass products. Featuring advanced grinding technology, the machine guarantees precise and consistent results. Its robust construction and user-friendly design make it suitable for both small workshops and large-scale production lines. The Glass Edge Processing Machine is a valuable addition to any glass processing setup, enhancing efficiency and product quality.]