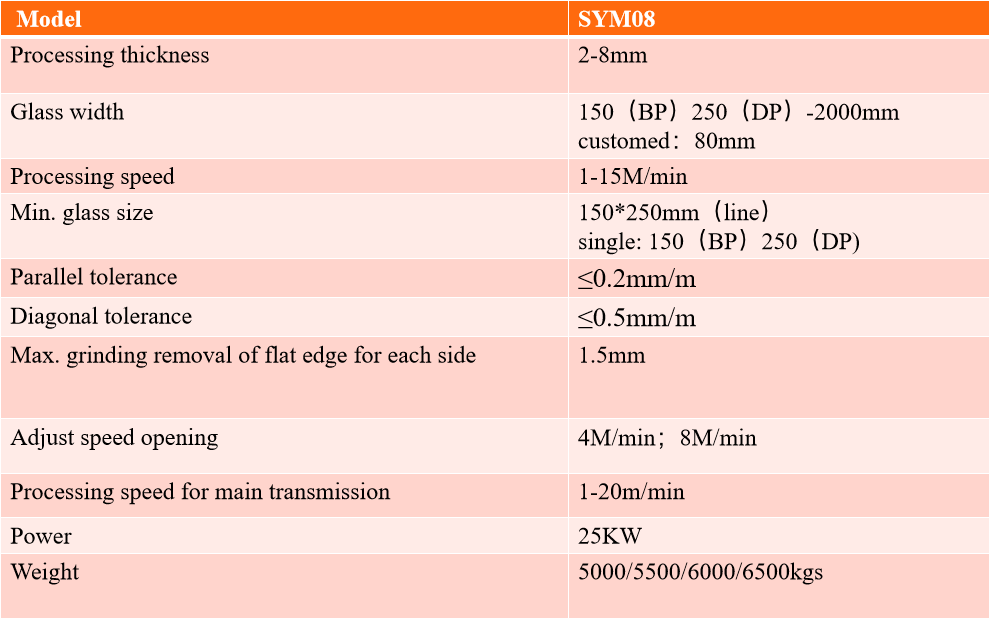

Technical Parameters of SYM08DP https://www.enkong.com/product-sm-08-series-glass-straight-line-pencil-edging-machine.html

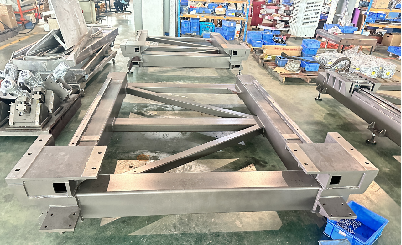

2. Introduction of base: Through systematic structural optimization and strengthening, we ensure the stability and durability of the machine under high-speed working conditions.

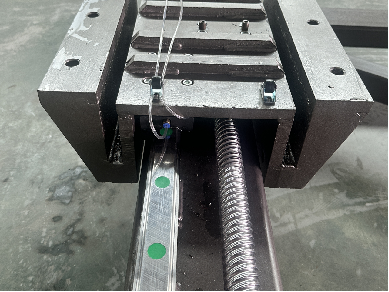

3. Intodeution of supporting frame:The supporting frame adopts "W" shape structure, the supporting frame of Glass Double Pencil Edging Machine can play the role of bidirectional balance and reduce the lateral force of ball screw and linear guide rail. the supporting frame of Glass Double Pencil Edging Machine has good deformation resistance, maintains the machining accuracy of the machine and extends the service life of the machine.

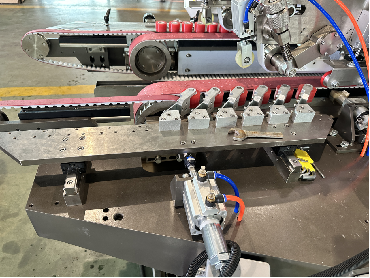

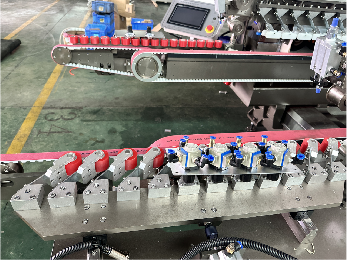

4. Infeed section modularization of Glass Double Pencil Edging Machine:Fixed side positioning component of double linear guide rail, easy and fast adjustment. Positioning module adopts double linear guide rail (handle directly adjustable) + spring plate + cylinder (buffer function)

4. Our girder through CNC machining of Glass Double Pencil Edging Machine, reduce its own errors, and better ensure the overall stability of the machine. The stress of the box girder has been reasonably optimized, and the overall rigidity has been increased by 30%. The beam is annealed and naturally aged to reduce the chance of later deformation of the machine. CNC deep processing to ensure the accuracy of assembly. Each grinding head seat is equipped with a force bar to strengthen the support and reduce the resonance wave. It makes sure a high-speed processing.

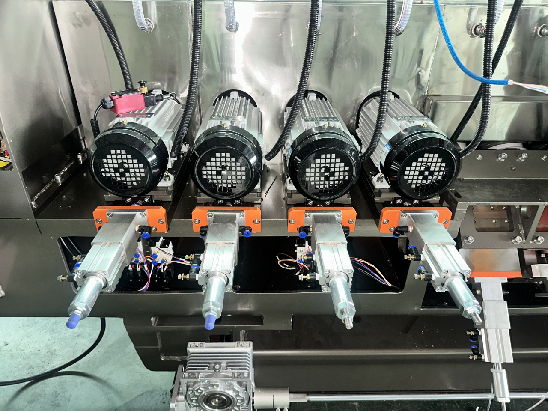

5. Grinding Head Bracket/Upper and Lower Chamfer Components of Glass Double Pencil Edging Machine: Grinding head bracket adopted modular design facilitates subsequent replacement and maintenance(Remove 4-6 screws to disassemble)The down chamfer structure adopted suspension structure, which does not need to be adjusted for glass of different thicknesses.

6.Our synchronous belt guide groove of glass double edging machine passes through the CNC gantry and is processed as a whole with PE board: PE board comes with oil and certain lubrication, which reduces belt wear, prolongs service life, and is less prone to jamming during operation. After the PE board is worn, it can be directly replaced without affecting the accuracy of the reference surface, and the maintenance cost is lower.

7. Our Glass Double Pencil Edging Machine adopting a mobile console centralized control system and HMI touch screen: Operators can view current and machine operation status from a movable control table and the current machine, achieving a dual monitoring system.

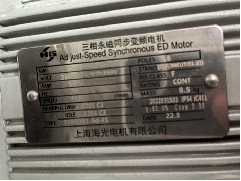

High speed two-stage drive assembly(Patented product):

This machine's motor adopted a high-speed motor with a two-stage transmission structure, which can increase the speed to about 4500rmp. The shaft can withstand the operation of 12000rpm to avoid the strong impact of glass on the grinding head motor when high-speed edging.

Accuracy reaches 0.002mm. Avoid the strong impact of glass on the grinding head motor when grinding at high speed, and greatly improve the effect and productivity of glass tempering.

A 36-month warranty is available.

Two different thicknesses of round edge wheels can be installed, and only the unused thickness grinding wheel needs to be withdrawn, it is more efficient.

Fully adaptive advance and retreat grinding wheel function(optional):

Through the servo system, real-time monitoring of grinding wheel during processing. Automatic operation to adjust feed or reduce grinding wheel to plate contact. Thus, it is not necessary to manually adjust the grinding wheel feed during processing until the grinding wheel is completely lost.

Super power consumption motor (optional):

compared with the general three-phase motor (2A) idling, we only need 1/10 of the current, according to the production of 12 hours a day, and the electricity cost is as high as 30,000 RMB per year.

Adaptive Air Suspension Polishing System of Glass Double Pencil Edging Machine(Patented product):

The polishing pressure of the chamfer and the bottom edge can complete the processing of each piece of glass in an absolutely balanced state.

Automatic infeed until the grinding wheel is used up, saving polishing the grinding wheel.With the high-speed two-stage transmission grinding head structure, the smoothness of the bottom edge after rough grinding is close to the smoothness of the glass surface, so there are no requirements for the quality of polishing wheel.