The super white float glass industry is experiencing increased competition, with glass edge grinding machines helping companies seize market opportunities.

In the early days, the number of super white float glass manufacturers was relatively small, mainly consisting of foreign companies such as PPG from the United States, Pilkington from the United Kingdom, Saint-Gobain from France, and Asahi Glass from Japan, whose prices were always high.

With the support of national policies, China's photovoltaic power generation industry has developed rapidly, and its cumulative installed capacity currently ranks first in the world. According to data released by the National Energy Administration, by the end of 2020, China's cumulative installed photovoltaic power generation capacity was 25.34GW, with 48.2GW of new installed capacity, an increase of 60.1% over the previous year. The booming photovoltaic power generation industry has driven an increasing demand for photovoltaic glass, thereby driving the growing demand for super white float glass.

To meet the demand of the photovoltaic power generation industry, the number of enterprises entering the super white float glass industry in China has been increasing, with South Glass Group, Xinyi Glass, Flatgroup Glass and Yuhua Glass in Henan being the representative ones. As the number of enterprises has increased, China's super white float glass capacity has continued to expand, and output has continued to grow, not only meeting the domestic market demand but also being exported to overseas markets in large quantities.

At present, the super white float glass market in China is in oversupply. Because super white float glass is an important raw material for the photovoltaic power generation industry, downstream customers pay close attention to the qualifications, scale, technology, and product quality of production enterprises, so the leading ultra-clear flat glass enterprises in the domestic market occupy a larger share and have certain market influence. Small-scale and weak enterprises, as well as new entrants, have limited development space. Overall, the entry threshold for the ultra-clear flat glass industry in China is relatively high.

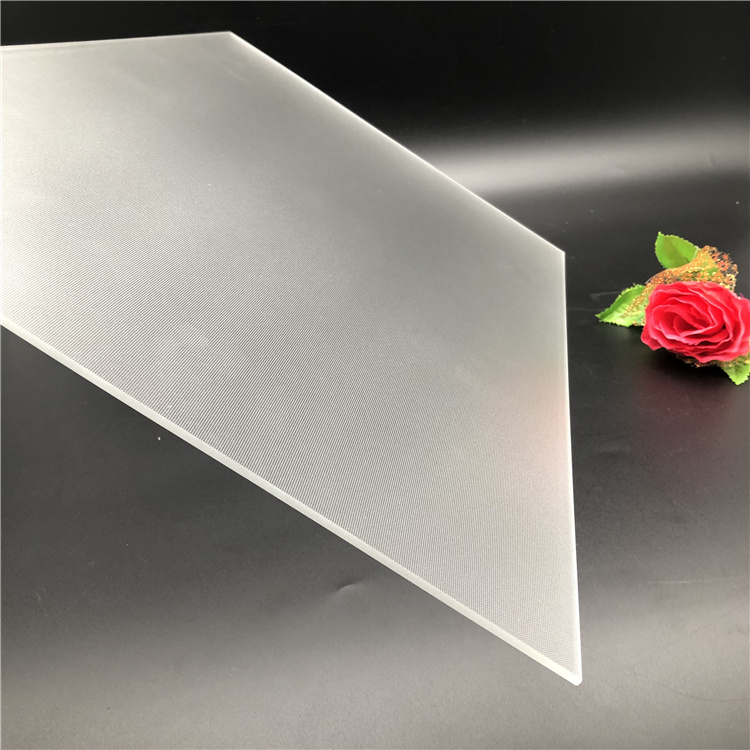

Super white float glass is a high-end architectural glass, and it is also the main product type of photovoltaic glass. The market space is broad, and under the drive of demand, the capacity of the ultra-clear flat glass industry in China has been expanding continuously since 2006. At present, China is the largest producer of ultra-clear flat glass in the world. There are many ultra-clear flat glass production enterprises in China, and the leading enterprises have a larger market share, with a high market concentration. It is difficult for new entrants to develop in this market.

With the rapid development of China's economy, the rise of industries such as construction, furniture, automobiles, and electronics has led to an increasing demand for glass materials, especially high-quality ultra-clear flat glass. In recent years, the number of enterprises that have laid out in the super white float glass industry has gradually increased, and market competition has become increasingly fierce. The market space is vast. Under such circumstances, an efficient glass edge grinding machine has become a weapon for enterprises to seize the market. The ENKONGS Glass Edge Grinding Machine, as a glass processing equipment, is mainly used for glass grinding, chamfering, polishing, etc., and is an indispensable equipment in the production process of ultra-white drawn glass. Its application advantages are as follows:

1. Improve production efficiency: The glass edge grinding machine adopts advanced grinding technology, which can achieve high-speed, high-precision edge grinding, greatly improving production efficiency and shortening the product production cycle.

2. Ensure product quality: The glass edge grinding machine adopts precise measurement systems and intelligent control systems to ensure consistency in glass edge grinding dimensions and smoothness, effectively improving product quality.

3. Reduce production costs: The glass edge grinding machine has a long service life and low maintenance cost, which can ensure product quality while reducing production costs for enterprises.

4. Adapt to diversified market demand: The glass edge grinding machine can achieve edge grinding processing of various shapes and specifications of glass, meeting the diversified and individualized market demand.

5. Environmentally friendly and energy-saving: The glass edge grinding machine uses environmentally friendly lubricants to reduce energy consumption and reduce environmental pollution.

In the context of fierce market competition in the ultra-white drawn glass market, having high-performance glass edge grinding machines means having a powerful weapon to seize the market advantage.