In the context of increasing demand for glass in the building, home furnishing, automotive industries and other sectors, how to improve glass processing efficiency and reduce material waste has become an urgent problem for the industry. As a key equipment in the glass processing process, how can glass edge grinding machines help reduce material waste and achieve cost savings? This article will reveal the answer.

I. The current situation of the glass industry: High demand, scarce resources

In recent years, with the rapid development of China's economy, the demand for glass in the building, home furnishing, and automotive industries has shown a sustained growth trend. The market size of the glass processing industry is expanding, but material waste is serious in the production process. How to improve the utilization rate of glass and reduce costs has become a major challenge for the industry.

II. The role of glass edge grinding machines: Improving utilization rate and reducing waste

1. High precision processing to meet diverse needs

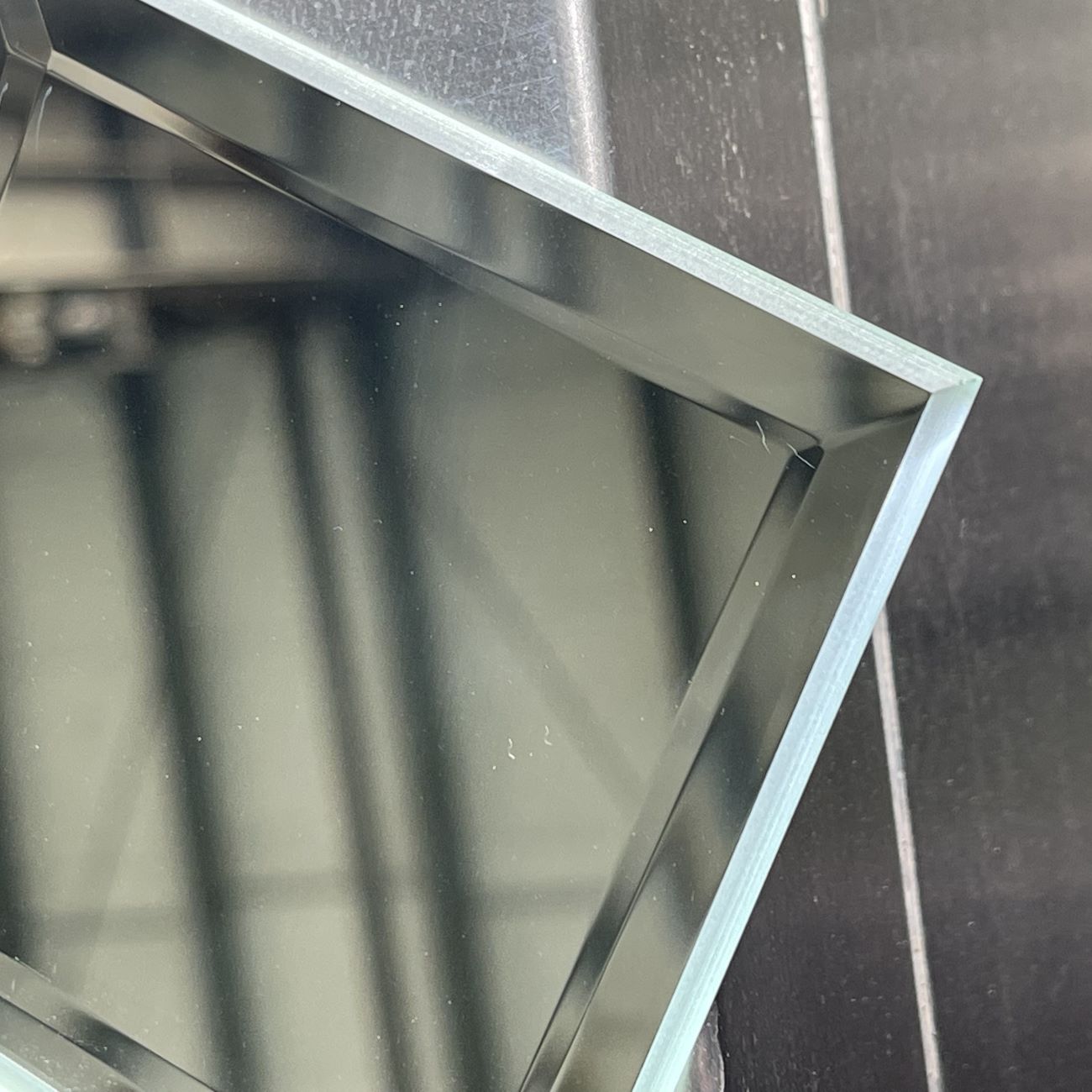

Glass edge grinding machines use advanced numerical control technology to achieve high precision and high-speed glass edge processing. Whether it is straight edge, round edge, chamfering, etc., glass edge grinding machines can easily handle them and meet the glass processing needs of various shapes. Through high precision processing, the glass edge is processed more beautifully and flat, improving the utilization rate of glass and reducing waste.

2. Saving raw materials and reducing costs

Glass edge grinding machines can process glass edges with high precision and smoothness, reducing the amount of glass required for subsequent processing. This not only saves raw materials but also reduces costs. In addition, by optimizing the processing parameters, the glass edge grinding machine can improve the processing efficiency and reduce the processing time, further reducing costs. The glass edge grinding machine can precisely control the cutting amount during the processing, avoiding excessive cutting that leads to material waste. At the same time, by optimizing the processing technology, it can reduce the damage to the glass edge and further improve the glass utilization rate. In the context of the continuous rise in raw material prices, the application of glass edge grinding machines can help reduce enterprise costs.

3. Improve production efficiency and shorten the construction period

Enkongs' glass edge grinding machine has a high degree of automation and can be operated by one person to operate multiple machines, greatly improving production efficiency. Compared with traditional manual edge grinding technology, Enkongs' glass edge grinding machine can complete a large number of glass edge processing tasks in a short time, shorten the construction period, and bring higher benefits to the enterprise.

4. Green and sustainable development

The glass edge grinding machine uses environmentally friendly coolants to reduce pollution during processing. At the same time, by improving the utilization rate of glass, it can reduce the generation of waste and help achieve green production and promote sustainable development of the industry.

III. Choosing a glass edge grinding machine: brand, performance, after-sales service

When selecting a glass edge grinding machine, enterprises should pay attention to the following points:

1. Brand strength: Choose a glass edge grinding machine brand with good reputation and market influence to ensure the quality of the equipment and after-sales service.

【Guangdong Enkongs Machinery CO., LTD & Jiangmen Enkongs Intelligent Technology CO., LTD (known as Enkong) are specializing in the research and development and production of edging equipment. The production workshop is located in Jiangmen city, Guangdong province. There are more than 100 employees. The workshop covers an area of 10,000 square meters.

Enkongs has three more decades of experience in precision machining and design of variety machinery parts.Enkongs has gradually developed into an enterprise integrating self-developed design, precision machining, assembly operations, after-sales service and import and export business.

Enkongs products have been widely used in glass (construction, solar, industrial glass), sintered stone, ceramic tiles industries and the enkongs product have been highly recognized by customers.】

2. Performance Parameters: Pay attention to the processing speed, precision, and cutting thickness of the glass edge grinding machine, ensuring that the equipment can meet the production needs of the enterprise.

3. After-sales Service: Understand the after-sales service policies provided by the manufacturer, such as equipment maintenance and technical support, to ensure that the equipment runs normally.

Conclusion:

Glass edge grinding machines play a crucial role in glass processing. By improving glass utilization and reducing material waste, glass edge grinding machines help enterprises achieve cost savings and increased efficiency. Selecting the right glass edge grinding machine will bring higher production benefits and sustainable development potential to the enterprise. How can glass processing be reborn? Enkongs' new glass edge grinding machine has already answered this question.