1.Product Description

1. XM351/XM351A Glass Straight-line Beveling Machines are used for grinding bevel and bottom edge of glass with different size and thickness. Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time.

2. It is easy to adjust the feeding of motor in the all and the one and beveling angle while glass thickness is being changed. Same thickness of glass sheet can be process continually. The brightness of finished surface will be almost the same as glass itself.

3. (Independent wool felt wheel + the cerium oxide ) make the flat edge more shining.

4. Input and output conveyor adopt timing belt which can improve the transmission precision.

5. Rear beam can be adjusted up and down which is suitable for processing small pieces of glass.

6. The electrical elements with famous ABB/ Schneider brand.

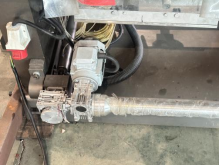

7. All mechanical feeding parts with lubricating system.

8. Glass Straight-line Beveling Machine is also used to process mosaic glass, inlay glass, spell mirror glass and craft glass ect.

9. XM351 can grind out the bevel angle of 3-30°arrises (5 rough and fine grinding + 3 polishing + 1 round bottom edge); XM351A can grind out the bevel angle of 3-45°arrises glass.

10. XM351Acan be raised and adjusted, and the later maintenance will be more convenient. The minimum processing size of 351A is 30*30mm. The minimum processing size of XM351 is 120*120mm.

11. The processing speed is adjustable with variator which offers a wide range of speed selection.

12. ENKONGS was set up in 2004, one of the famous manufacturers of glass equipment.We has our own CNC center to processing all machanical parts for our glass machine. Quality control in the house.

13. ENKONGS accepts reasonable custom-made.

2. Parameter

Type | XM351 | XM351A |

Spindles QTY | 9PCS | 9PCS |

Min. Glass size | 120*120mm | 30*30mm |

Processing glass thickness | 3-19mm | 3-19mm |

processing speed | 0.8-4.1m/min | 0.8-4.1m/min |

Weight | 3800 KGS | 4250kg |

Installation power(kw) | 19.08kw | 22.83kw |

Occupied size(mm) | 7700*1400*2500mm | 7800*1400*2500mm |

Arris | 30° | 45° |

Bevel width | 40mm | 40mm |

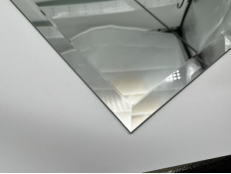

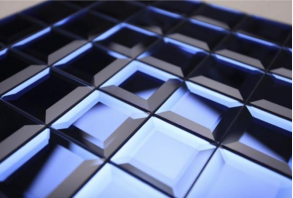

3.Glass sample

XM351

XM351A

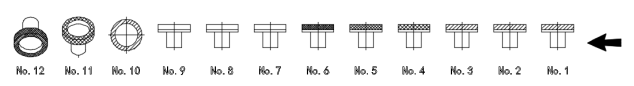

4.Wheels arrangement

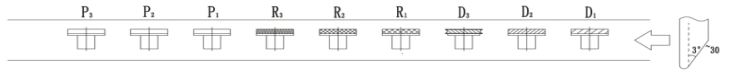

XM351

XM351A

XM351 Wheel arrangement

NO. |

Wheels |

Specification |

Function |

NO.1 | Flat edge diamond wheel | Φ150*Φ12*100mesh |

Rough beveling |

NO.2 | Flat edge diamond wheel | Φ150*Φ12*180mesh | |

NO.3 | Round edge diamond wheel | Φ175*Φ22*R5*180mesh | bottom grinding (pencil edge) |

NO.4 |

Resin wheel |

Φ150*12*20*13 3# 170mesh |

Bevel grinding |

NO.5 | Resin wheel | Φ150*12*20*13 5# 325mesh | |

NO.6 |

Resin wheel |

Φ150*12*20*13 5# 325mesh | |

NO.7 | Wool felt | Φ150*Φ105*35 |

Bevel polishing |

NO.8 |

Wool felt | Φ150*Φ105*35 | |

NO.9 |

Wool felt

|

Φ150*Φ105*35

|

XM351A Wheel arrangement

NO. |

Wheels |

Specification |

Function |

NO.1 | Beveling diamond wheel | Φ150*Φ12*100mesh |

Rough beveling |

NO.2 | Beveling diamond wheel | Φ150*Φ12 *180mesh | |

NO.3 | Round edge diamond wheel | Φ175*Φ22*R5*180mesh |

bottom grinding (pencil edge) |

NO.4 | Resin whee | Φ150*12*20*13 240mesh |

Bevel grinding |

NO.5 | Resin wheel | Φ150*12*20*13 325mesh | |

NO.6 | Resin wheel | Φ150*12*20*13 600mesh | |

NO.7 | Wool felt wheel | Φ150*Φ105*35 |

Bevel polishing |

NO.8 | Wool felt wheel | Φ150*Φ105*35 | |

NO.9 | Wool felt wheel | Φ150*Φ105*35 |

5.The processing center for processing mechanical parts

The front and rear reinforced casting girders,columns and basesare subjected to secondary heat treatment,so that the welding parts have a qualitative change, which can strengthen the hardness and make the machine more durable. Spare parts are processed by CNC gantry machining center,which reduce the cumulative tolerance of the whole assembly and improve the precision of edge grinding.

6. The edging assemble worksh

7.  The close-up photos and description of edger

The close-up photos and description of edger

|

|

| |

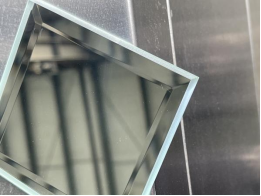

The lathe of edger, after grinding, milling ,drilling ,painting . the beams of edgers

Adopt reinforcement design to prevent beam deformation | |||

|

| ||

The front and rear chain plates adopt double chains plus suspension structure, the

clamping force is constant,easy to load and unload. | |||

| | ||

Swing Angle motor, you can adjust the glass angle you want and it is very convenient; The processing speed controlled by Stepless motor, But it can be upgrade as Frequency

conversion | |||