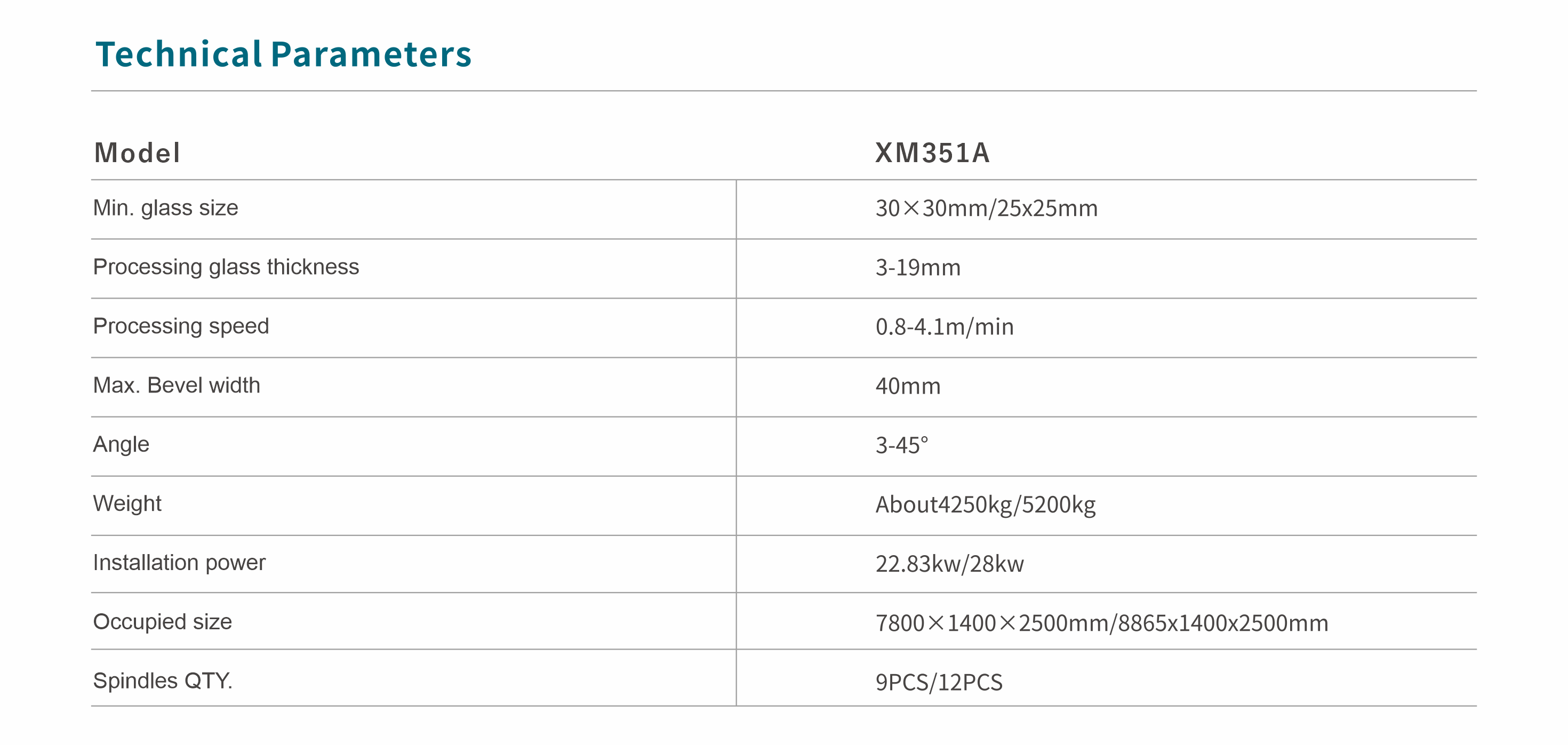

ENKONGS XM351A Glass Straight-line Beveling Machines is used for grinding bevel and bottom edge of glass with different size and thickness. Rough grinding, fine grinding, polishing of bevel and grinding of bottom edge can be completed in one time. It is easy to adjust the feeding of motor in the all and the one and beveling angle while glass thickness is being changed. Same thickness of glass sheet can be process continually.

ENKONGS' Glass Straight Line Beveling Machine is a specialized tool used in the glass industry for grinding and edging glass. This machine is designed to create precise beveled edges on glass panels, giving them a polished and professional look.

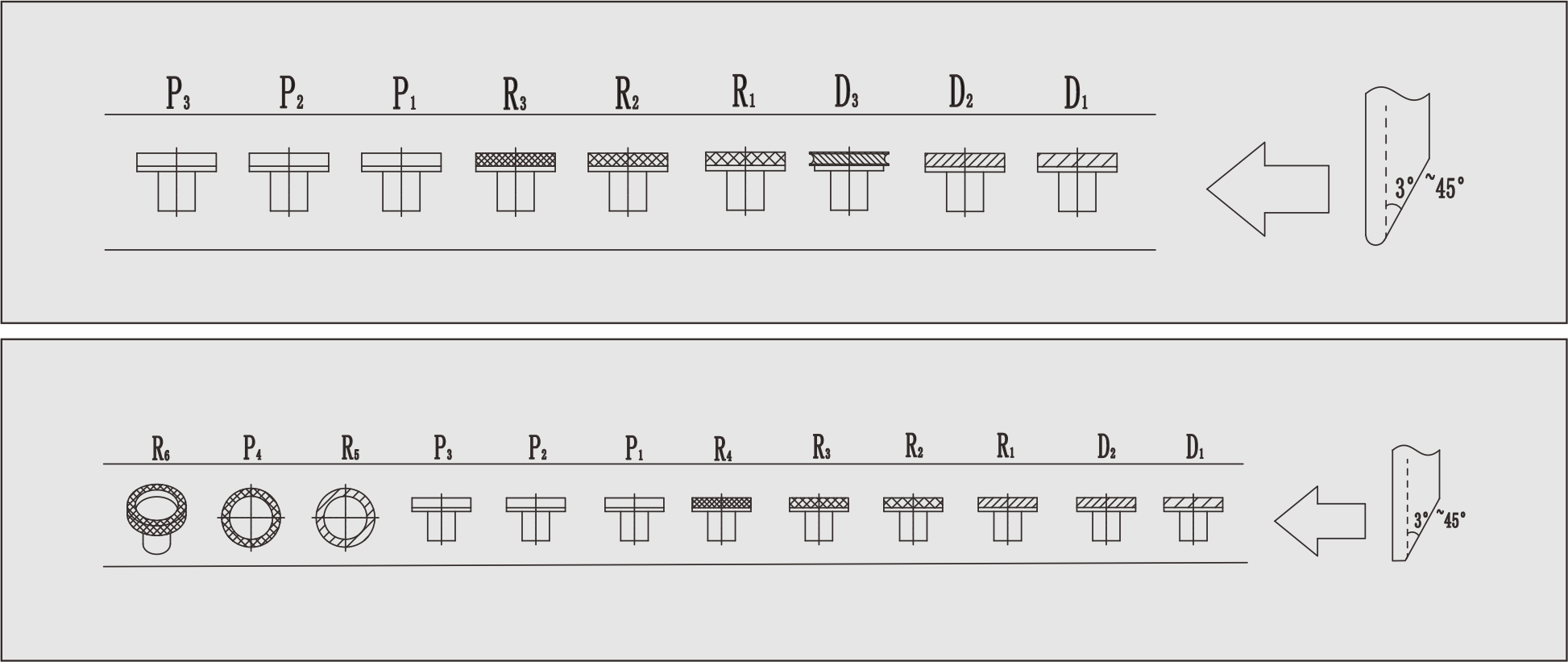

The process of beveling glass involves grinding down the edges of the glass at an angle, creating a smooth and decorative finish. The Straight Line Beveling Machine uses diamond-coated grinding wheels to achieve this, ensuring a high-quality result every time.

The base is made of carbon steel and welded together. It has undergone heat treatment by our in-house CNC deep processing center to effectively avoid stress failure and prevent it from deforming. The base is treated with anti-rust, which can increase the service life of the machine.

ENKONGS columns of glass straight-line beveling machine is welded from carbon steel. A machine has 2 such columns, which makes the machine more stable and ensures that the subsequent machine is not prone to shaking when running at high speed.

ENKONGS

The main features of the glass straight-line beveling machine include.

High-Speed Grinding and Polishing: These machines are designed for high-speed production environments, allowing for fast grinding and polishing of straight glass edges. This is particularly important in industries where large quantities of glass need to be processed quickly and efficiently.

Adjustable Bevel Angles and Speed: The machine offers adjustable bevel angles, allowing operators to customize the angle of the bevel depending on the specific requirements of the project. The speed of the grinding and polishing process can also be adjusted to suit the type of glass being processed.

Integrated Conveyor System: The glass straight-line beveling machine often includes an integrated conveyor system that moves the glass through various stages of the beveling process. This system improves efficiency and ensures consistent results.

Glass Grinding Equipment

Glass grinding equipment plays an essential role in the beveling process, as it is used to grind and shape the edges of the glass. Grinding equipment for glass typically includes specialized grinding wheels that can be made of diamond, resin, or other abrasive materials. The grinding process smooths the edges of the glass and prepares them for further processing, such as polishing or coating.

The key features of ENKONGS mosaic glass edging machine include.

Precision Control: Given the small size of the glass pieces, precision control is essential in ensuring that the beveled edges are uniform and consistent. The machine must be able to handle different shapes and sizes of glass, which requires flexibility in terms of speed and angle adjustment.

Compact Design: The mosaic glass edging machine is designed to be compact and versatile, allowing for easy integration into small-scale production lines or workshop settings. Its small size makes it suitable for use in environments where space is limited.

Customizable Bevel Angles: The machine typically offers customizable bevel angles, allowing operators to adjust the angle of the bevel to suit the specific requirements of the mosaic design.

Glass beveling is a process in which the edges of the glass are ground and polished to create a beveled, angled effect. The angle of the bevel can vary, but it typically ranges to 45 degrees. This technique enhances the visual appeal of glass, giving it a smooth, polished edge that can be used for decorative purposes or to create functional designs. Beveled edges are particularly popular in glass panels used for mirrors, windows, table tops, and glass doors, as well as in mosaic glass work and intricate glass designs.

The purpose of beveling is twofold: it adds to the aesthetic value of the glass and improves safety by eliminating sharp edges that could cause injury. The glass beveling equipment used for this process includes a variety of machines tailored to different applications, such as mosaic glass edging machines, small glass beveling machines, and glass straight-line beveling machines.

ENKONGS glass beveling edging machine is an essential piece of equipment in the glass processing industry, designed to create beveled edges on glass panels with high precision.This machine is primarily used for edging glass sheets at specific angles, typically ranging from 3° to 45°, to create a smooth, aesthetically pleasing edge. The glass beveling edging machine is equipped with grinding and polishing wheels that efficiently shape the glass edges while ensuring a high-quality finish. These machines are vital for industries that require both the decorative enhancement and safety of glass products, such as mirrors, architectural glass, and furniture. With advanced features such as variable speed control, adjustable bevel angles, and automated feeding systems, the glass beveling edging machine ensures consistent results and high throughput in both large-scale manufacturing and specialized custom jobs.

The performance of a glass beveling edging machine is defined by its ability to handle various glass sizes and types, offering flexibility for different processing needs. Modern glass beveling edging machines come with advanced control systems that allow operators to adjust the bevel angle and processing speed with precision, ensuring the correct angle for each glass type. The machine uses high-quality grinding wheels made from materials like diamond or resin, which are essential for achieving a precise and clean bevel. Additionally, the polishing sections of the glass beveling edging machine further enhance the finish, ensuring smooth, glossy edges without any scratches or irregularities. The high efficiency of these machines makes them indispensable in large-scale operations, where uniformity and speed are critical to meeting production deadlines while maintaining high standards of quality.

ENKONGS glass beveling edging machine is highly versatile and is used across various industries. In the construction and architecture sector, it is used for beveling glass panels for windows, facades, and glass doors, providing both safety and aesthetic appeal. In the mirror industry, the glass beveling edging machine creates decorative beveled edges that are integral to the design of mirrors and reflective surfaces. Furthermore, the machine is extensively used in the production of glass furniture, such as tabletops and display cases, where beveling adds a touch of elegance. Custom glass shops also rely on glass beveling edging machines for creating intricate designs in glass art and mosaics. Whether for functional or decorative purposes, the glass beveling edging machine plays a critical role in shaping the glass industry by delivering high-quality products that meet diverse customer needs.

In addition to creating beveled edges, this machine can also be used for straight line grinding and edging of glass. This makes it a versatile tool for glass manufacturers and fabricators, allowing them to create a variety of glass products with different finishes.

The Straight Line Beveling Machine is easy to operate and requires minimal maintenance, making it a cost-effective solution for businesses in the glass industry. With its precision and efficiency, this machine is a valuable asset for any glass processing facility.

Overall, the Straight Line Beveling Machine is an essential tool for creating high-quality, decorative glass products. Its ability to grind and edge glass with precision and consistency makes it a must-have for any glass manufacturer looking to produce top-notch products.

XM351A offer a wide range of advantages, including precision, efficiency, versatility, and high-quality finish.Its applications span across various industries, including architecture, furniture, automotive, and art. With its ability to enhance the aesthetic appeal of glass panels, this machine plays a crucial role in the modern glass industry.