ZM9 glass straight-line edging machine is suitable for different size and thickness flat edge glass grinding, its rough grinding、fine grinding and polishing finish in one time; the polishing flat is similar to the smooth degree of glass body, While adjusting the different processing thickness,(you can reference the digital display in front beam to adjust);front chamfer motor can move synchronically with front beam; with advanced structure; high precision,easy operation. It is the necessary tool for glass machinery.

2.Product Description

It is used to grinding straight edges on a flat glass &45arrises of different sizes and thicknesses. The rough grinding, precise grinding, and angel making can be finished at one time.

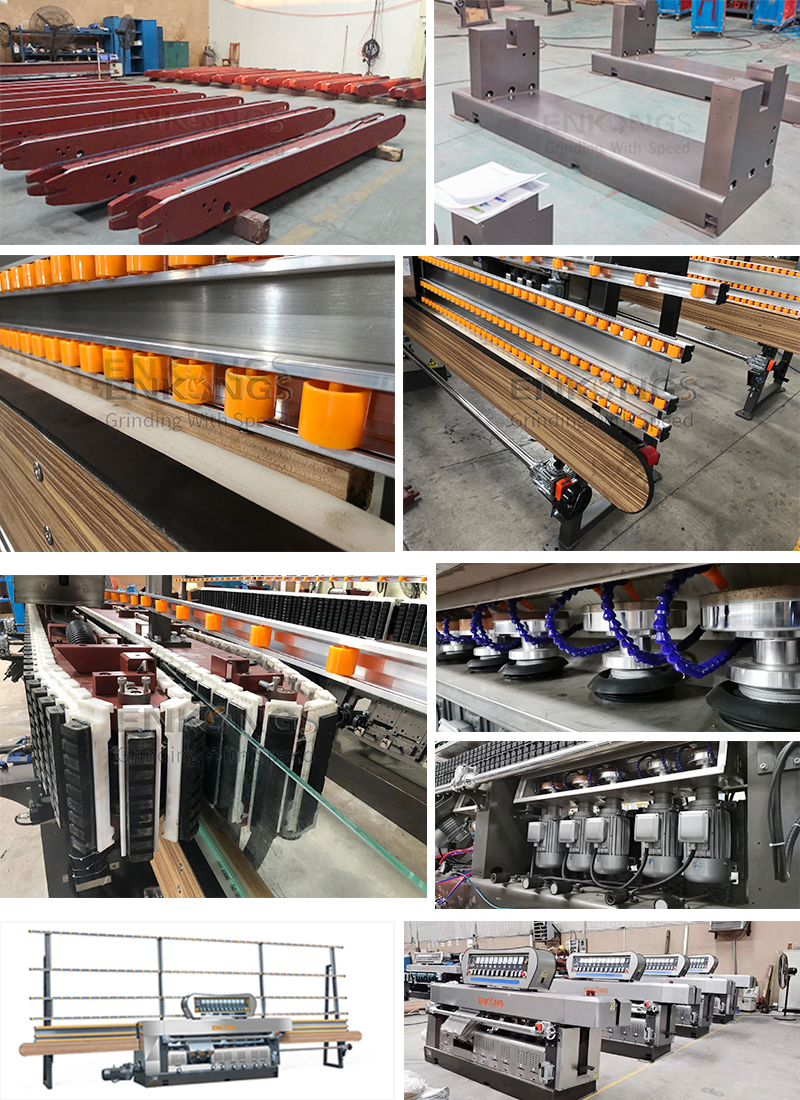

A special design of the in-feed section for controlling the desired amount of glass removal without adjusting each spindle individually.

(Independent wool felt wheel + the cerium oxide ) make the flat edge more shining.

Input and output conveyor adopt timing belt which can improve the transmission precision.

When adjusting different processing thicknesses, the former arris grinding head can move simultaneously along with the front beam.

The electrical elements with famous ABB/ Schneider brand.

All mechanical feeding parts with lubricating system.

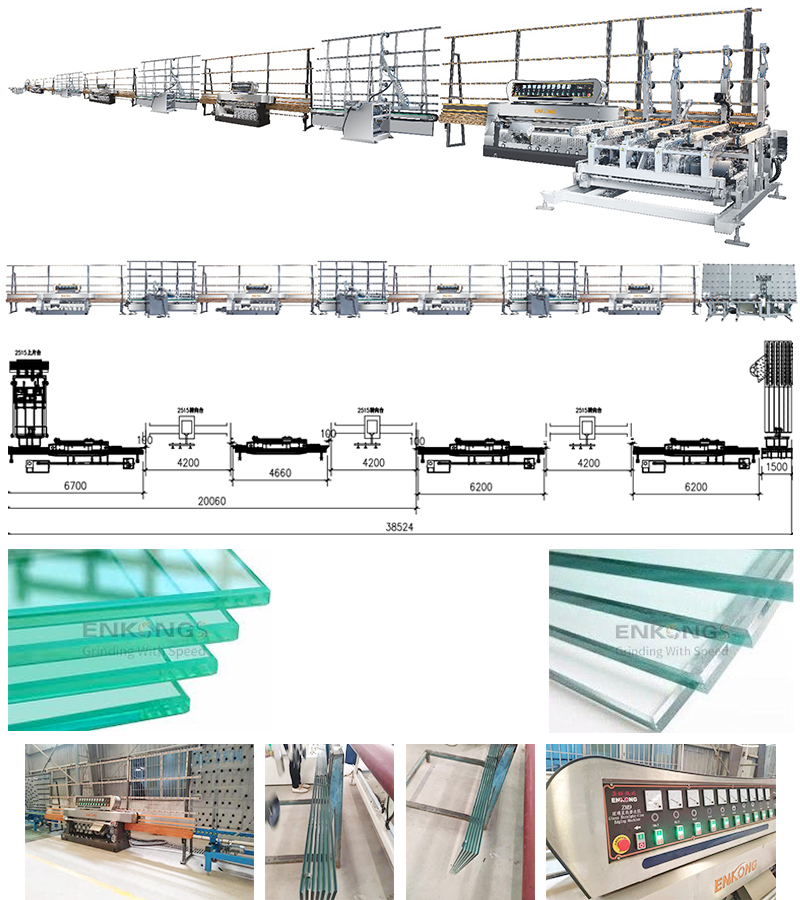

It can continuously process for the same thickness with different sizes. It can be combine as vertical edging production line. it made up by 4sets of edgers+3sets of turning table+1set of vertical washing machine. This production line is special for processing glass shower doors.

ZM9 Edger with three operation mode: Manual. Digital display and PLC Control+touch screen+pneumatic polishing(NO.4,6,8,9)

ENKONGS was set up in 2006, one of the famous manufacturers of glass equipment.We has our own CNC center to processing all machanical parts for our glass machine. Quality control in the house.

ENKONGS accepts reasonable custom-made.

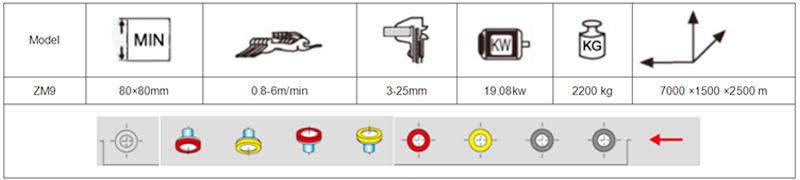

Technical parameter

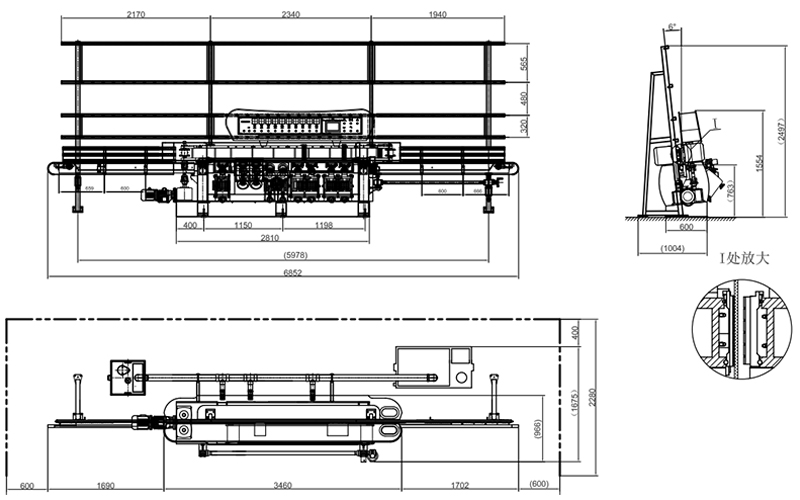

Lay-out

CLOSE-UP details

Projects

Machining center

Certificate

Service